- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

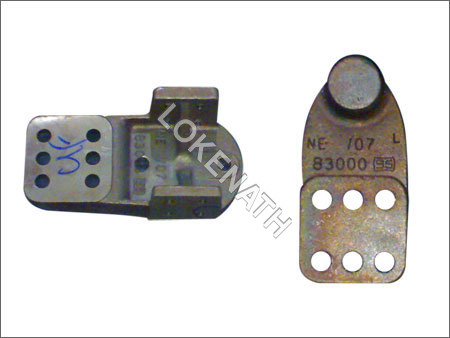

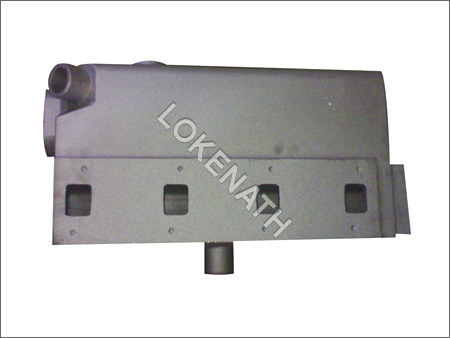

Aluminium Sand Casting

350 INR/Bale

Product Details:

- Product Type Industrial Casting

- Casting Process Manual Molding, Machine Molding

- Application Automotive Parts, Industrial Machinery, Engineering Components

- Method Sand Casting

- Surface Treatment Shot Blasting, Sandblasting, Polishing

- Weight (kg) Customizable as per requirement

- Color Silver Grey

- Click to view more

X

Aluminium Sand Casting Price And Quantity

- 350 INR/Bale

- 1 Unit

Aluminium Sand Casting Product Specifications

- Manual Molding, Machine Molding

- Sand Casting

- Automotive Parts, Industrial Machinery, Engineering Components

- Industrial Casting

- Customizable as per requirement

- Silver Grey

- Shot Blasting, Sandblasting, Polishing

Aluminium Sand Casting Trade Information

- Paypal

- Yes

- Asia

- All India

Product Description

In the wake of the constantly rising demand for trustworthy products, we are affianced in manufacturing, supplying and exporting a comprehensive range of Industrial Aluminium Sand Casting. These Aluminium sand castings are widely find their applications in automobile industries for various locomotive applications. We offer our range of Industrial Aluminium Sand Casting in different sizes and weights as per the specific requirement of our esteemed patrons.

Features

- Easy installation

- Fine finishing

- Longer life

- Pattern Creation: A reusable pattern, resembling the final part, is made from wood, metal, or other materials.

- Mold Making: The pattern is placed in a flask (a box) and surrounded by sand, which is compacted to form the mold.

- Gating System: Runners and risers are incorporated into the mold to guide the molten aluminum and manage the flow of metal.

- Pouring: Molten aluminum is poured into the mold cavity.

- Cooling and Solidification: The aluminum cools and solidifies within the mold.

- Mold Removal: The sand mold is broken away, and the casting is extracted.

- Finishing: The casting undergoes cleaning, removal of rough edges, and potentially other finishing processes to meet specifications.

- Versatility: Suitable for producing a wide range of shapes and sizes, including complex geometries.

- Cost-Effectiveness: Relatively low tooling costs compared to other casting methods, making it suitable for both low and high-volume production.

- Large Part Production: Can produce very large aluminum components.

- Suitable for Various Alloys: Can be used with different aluminum alloys, each with specific properties.

- Established Process: Sand casting is a well-established and widely understood method in metal casting.

- Automotive: Engine blocks, transmission housings, wheels.

- Aerospace: Structural components, engine parts.

- Electronics: Heat sinks, enclosures.

- Industrial Equipment: Pumps, valves, compressors.

- Sporting Goods: Bicycle frames, golf clubs.

- Construction: Architectural components.

Process Overview:

Key Features and Benefits:

Applications:

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email