- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Bronze Casting

- Aluminum Castings

- Leak Proof Casting

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Non Ferrous Castings

- Power Distribution Casting

- Impeller Bronze Casting

- Sand Casting

- Aluminium Sand Casting

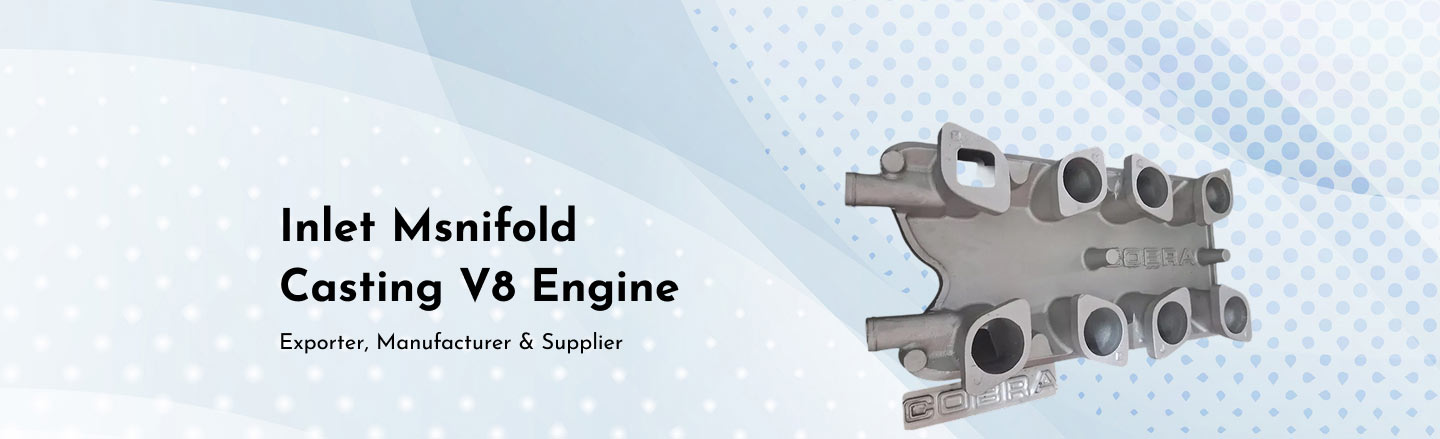

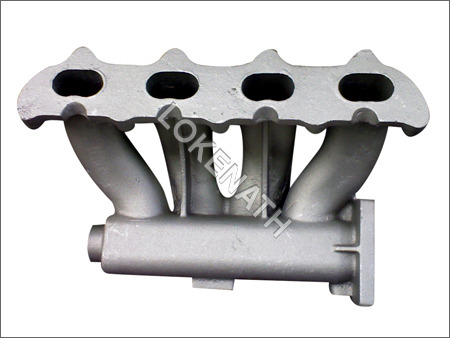

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

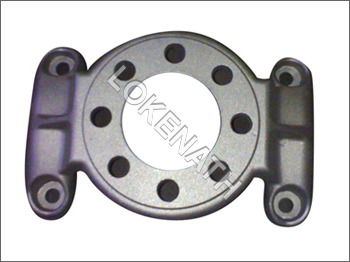

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

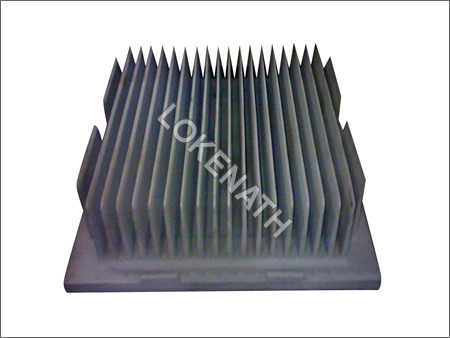

Aluminum Heat Sinks

Product Details:

- Product Type Aluminum Heat Sink

- Casting Process Die Casting

- Application Electronics, Lighting, Power devices

- Method Extrusion

- Surface Treatment Anodized

- Weight (kg) 0.25

- Color Silver

- Click to view more

X

Aluminum Heat Sinks Price And Quantity

- INR

- 1 Unit

Aluminum Heat Sinks Product Specifications

- Die Casting

- Aluminum Heat Sink

- Extrusion

- Anodized

- Silver

- 0.25

- Electronics, Lighting, Power devices

Aluminum Heat Sinks Trade Information

- as per requirements Per Day

- As per requirement Days

- Yes

- As per requirement

- All India

Product Description

We bring forth a huge gamut of Aluminum Heat Sinks for our valuable patrons, which are manufactured by using high conductivity and high purity aluminum to enhance their quality. These heat dinks are widely used thermal conduction to cool the mounted electronic device. Manufactured in compliance with international quality, clients can avail this Aluminum Heat Sinks from us in different specifications as per the specific industrial requirements.

Features

- Excellent cooling efficiency

- Easy and free movement

- Less maintenance

Efficient Thermal Management

Designed with precision finned shapes and high-grade anodized aluminum, our heat sinks maximize airflow and heat transfer. This ensures the effective cooling of sensitive electronic components, such as LEDs, power transistors, and ICs, maintaining device longevity and stability under rigorous conditions.

Versatile Application & Easy Installation

The screw mount feature allows straightforward attachment across various platforms, making our heat sinks ideal for electronics assemblies, lighting systems, and power device housings. Their adaptable dimensions and lightweight structure support both industrial and commercial settings with minimal installation effort.

FAQs of Aluminum Heat Sinks:

Q: How are these aluminum heat sinks installed in electronic devices?

A: These heat sinks use a screw mount design, allowing easy and secure attachment to a wide range of electronic boards and device enclosures. Simply align the sink with the component, insert screws through the mounting holes, and tighten to ensure optimal thermal contact.Q: What types of electronic components are these heat sinks compatible with?

A: Our aluminum finned heat sinks are suitable for cooling LED lights, power transistors, and integrated circuits (ICs), making them versatile for use in electronics, lighting systems, and power devices.Q: When should I consider using an aluminum finned heat sink?

A: Use these heat sinks whenever electronic or lighting devices generate excessive heat that could compromise performance or lifespan, such as high-power LEDs, amplifiers, or power ICs in continuous operation.Q: Where can these heat sinks be effectively utilized?

A: These heat sinks can be deployed in electronic circuits, lighting fixtures, power supplies, and industrial control systemsespecially where reliable and compact thermal management is required.Q: What is the manufacturing process for these heat sinks?

A: Our heat sinks are crafted through extrusion and die casting from high-quality aluminum, then surface treated with anodization to enhance corrosion resistance and durability.Q: How does anodized surface treatment benefit these heat sinks?

A: Anodizing enhances the aluminums resistance to corrosion, increases its surface hardness, and improves heat dissipation performance, making these sinks more durable for demanding applications.Q: What are the main advantages of using these aluminum heat sinks in power devices?

A: These heat sinks efficiently dissipate heat, prevent overheating, and ensure consistent operation of sensitive power electronics, all while maintaining a lightweight, compact form ideal for modern assemblies.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email