- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Bronze Casting

- Aluminum Castings

- Leak Proof Casting

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

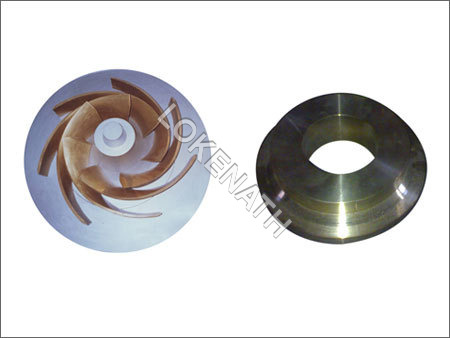

- Non Ferrous Castings

- Power Distribution Casting

- Impeller Bronze Casting

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

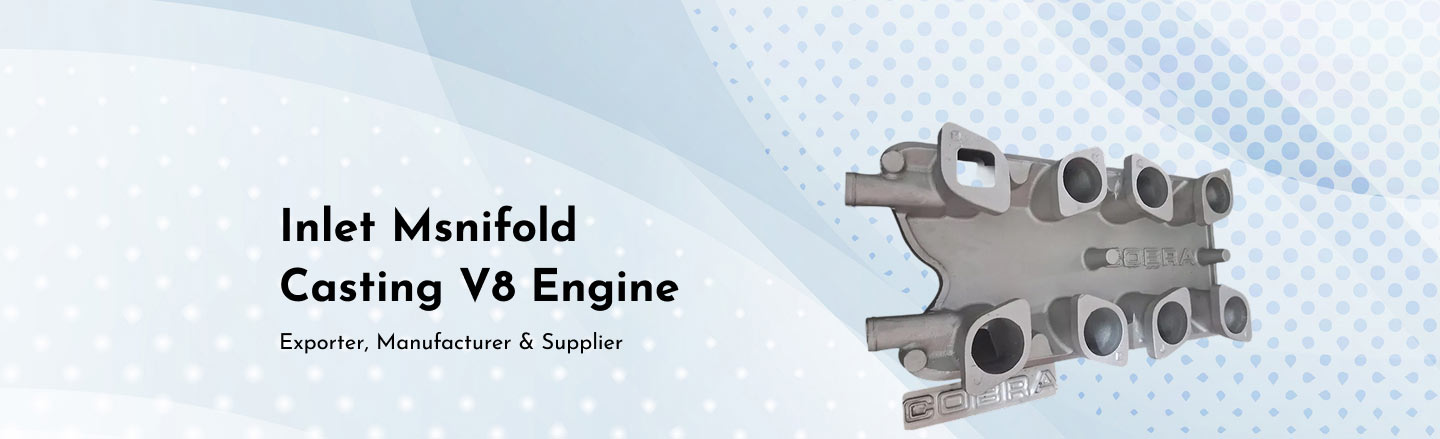

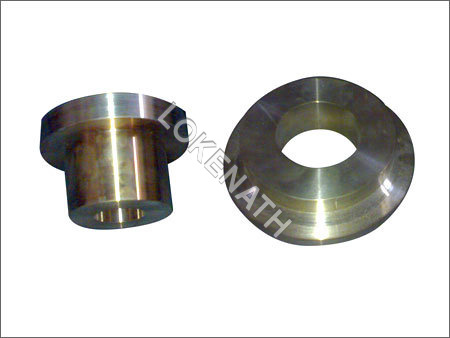

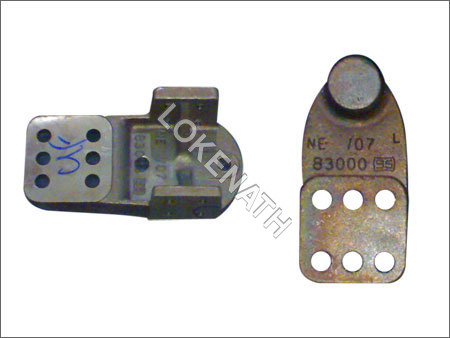

Bronze Casting

1500 INR/Piece

Product Details:

- Product Type Finished Bronze Casting

- Casting Process Sand Casting

- Application Industrial Machinery, Valves, Pumps, Art and Sculpture

- Method Casting

- Surface Treatment Polished

- Color Golden Bronze

- Click to view more

X

Bronze Casting Price And Quantity

- 1 Unit

- 1500 INR/Piece

Bronze Casting Product Specifications

- Sand Casting

- Finished Bronze Casting

- Casting

- Golden Bronze

- Polished

- Industrial Machinery, Valves, Pumps, Art and Sculpture

Bronze Casting Trade Information

- Per Day

- Days

- Yes

- Asia

- All India

Product Description

With the perfect combination of a highly motivated team of professionals & advanced machines, we manufacture and supply a wide range of Aluminium Bronze Castings. Specially designed for valve fittings and pumps, these bronze castings are suitable for high speed as well as heavy pressure bearings. We offer our Aluminium Bronze Castings range in different sizes, weight and dimensions as per the application requirements of our client.

Features

- Sturdiness

- Perfect finish

- Durable

Bronze casting is a method of creating metal objects, especially sculptures, by pouring molten bronze alloy (copper and tin) into a mold. The process, most commonly the lost-wax method, involves creating an original sculpture, making a wax replica, encasing it in a ceramic shell that hardens as the wax melts away, and then filling the hollow mold with liquid bronze. After the bronze cools, the mold is broken, and the finished bronze piece is removed, chiseled, finished, and sometimes chemically treated to achieve a patina.

How Bronze Casting Works

- Original Model: The process begins with a sculpture created in clay or another material.

- Wax Model: A wax model of the original is made, detailing its form and texture.

- Ceramic Shell: The wax model is covered in a thick, fireproof ceramic shell.

- Lost Wax: The entire assembly is heated, causing the wax to melt and drain away, leaving a hollow space within the ceramic shell that is a perfect negative of the original sculpture.

- Pouring Bronze: Molten bronze is poured into the hollow ceramic mold, filling the space left by the wax.

- Cooling and Demolding: After the bronze cools and hardens, the ceramic shell is broken away with a hammer and chisel.

- Finishing: The rough bronze piece is then finished by removing sprues (channels for metal flow), grinding, sandblasting, and applying a chemical patina for color and a final protective wax coat.

Why Bronze is Used

-

Bronze expands slightly before setting and constricts as it cools, which captures even the finest details from the mold.

-

It is a durable and weather-resistant metal, making it ideal for both outdoor and indoor applications.

-

Bronze has a lower melting point than many other metals, making it easier to work with.

-

It is used for a wide range of objects, including sculptures, musical instruments, medals, and industrial parts.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email