- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Bronze Casting

- Aluminum Castings

- Leak Proof Casting

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Non Ferrous Castings

- Power Distribution Casting

- Impeller Bronze Casting

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

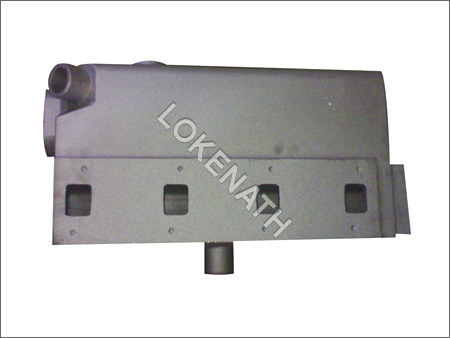

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

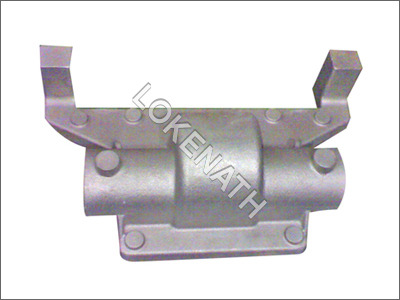

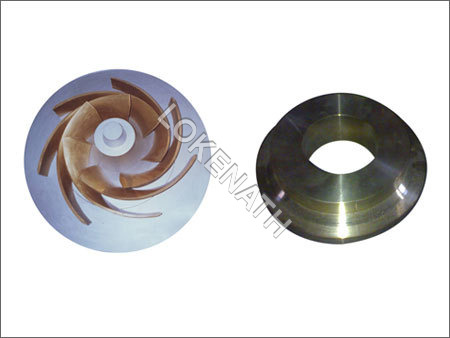

Impeller Bronze Casting

200 INR/Buckle

Product Details:

- Product Type Impeller Bronze Casting

- Casting Process Sand Casting / Lost Wax Casting

- Application Industrial Pumps, Marine Equipment, Water Treatment Plants

- Method Casting

- Surface Treatment Polished

- Weight (kg) 5 to 50 kg

- Color Golden Bronze

- Click to view more

X

Impeller Bronze Casting Price And Quantity

- 200 INR/Buckle

- 1 Unit

Impeller Bronze Casting Product Specifications

- Impeller Bronze Casting

- Polished

- Industrial Pumps, Marine Equipment, Water Treatment Plants

- Golden Bronze

- Sand Casting / Lost Wax Casting

- Casting

- 5 to 50 kg

Impeller Bronze Casting Trade Information

- Yes

- Asia

- All India

Product Description

Based in Faridabad, Haryana, India, we are one of the leading manufacturers, exporters and suppliers of Impeller Bronze Casting. Helps in smooth functioning of various bearing applications even under harsh conditions, these castings are suitable for various industries such as automobile and engineering. Designed using quality alloys in accordance with BSS LM series, DIN, ASTM and Indian standards, this Impeller Bronze Casting range is available in different weights ranging from 100 grams to 300 kgs (single piece).

Features

- Excellent quality

- Dimensional accuracy

- Long life

-

Typically made from bronze alloys such as LG2, AB2, or Gunmetal.

-

Commonly produced through sand casting, but other methods like gravity casting, low pressure die casting, and high pressure die casting can also be used.

-

Impellers usually feature a cylindrical shape with an open inlet (eye), vanes for directing fluid, and a bore for attaching to a driveshaft.

-

They accelerate the fluid outwards, and the velocity generated is converted into pressure when the fluid is confined by the pump casing.

-

Used in a wide range of industries including marine, oil and gas, chemical processing, and water treatment.

-

Bronze offers excellent corrosion resistance in various environments, high strength and durability, good wear resistance, and non-sparking characteristics.

-

Bronze impellers are often machined to precise dimensions and dynamically balanced to ensure optimal pump performance, according to Brass Neutral Links.

- Marine and Shipbuilding: Used in seawater and ballast pumps.

- Oil and Gas: Employed in offshore and refinery pumps.

- Chemical Processing: Handles aggressive chemical fluids.

- Water Treatment Plants: Used in sewage and clean water pumps.

- HVAC and Refrigeration: Circulation pumps in cooling systems.

- Bronze casting is a versatile process that allows for the creation of impellers with complex geometries and specific performance requirements.

- The choice of bronze alloy and casting method depends on the specific application and performance demands.

- 3D sand printing is also being utilized in impeller casting, offering benefits like optimized blade tips, reduced post-processing, and design flexibility.

Bronze impeller castings are rotating components, typically used in pumps, made from bronze alloys through a casting process. These impellers are designed to transfer fluid by accelerating it outwards from the center of rotation, converting rotational energy into kinetic energy. Bronze is a favored material due to its excellent corrosion resistance, high strength, wear resistance, and non-sparking properties, making it suitable for various applications, including marine, chemical, and water treatment.

Key Characteristics of Bronze Impeller Castings:

Examples of Bronze Impeller Casting Applications:

Additional Details:

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email