- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

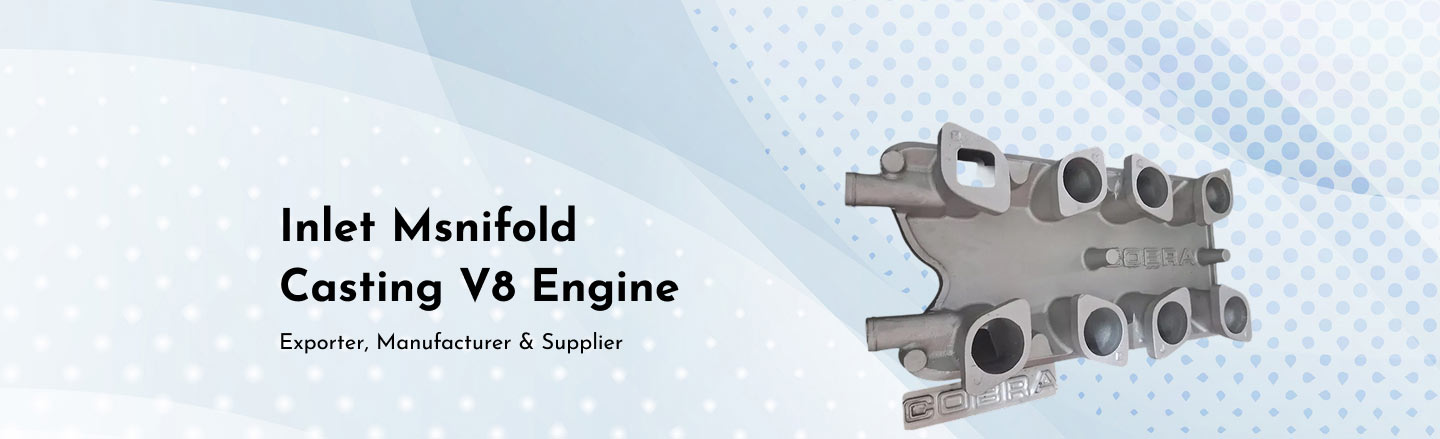

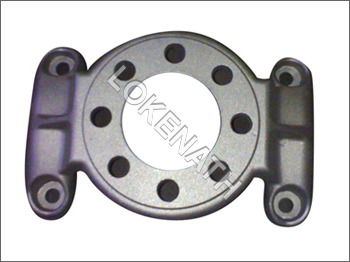

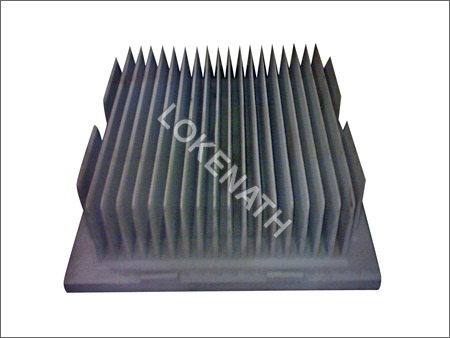

Gravity Die Castings

Product Details:

- Product Type Industrial Casting

- Casting Process Pressure Die Casting

- Application Automotive, Engineering, Electrical Industries

- Method Gravity Die Casting

- Surface Treatment Polished

- Weight (kg) 1 to 25 kg

- Color Silver

- Click to view more

X

Gravity Die Castings Price And Quantity

- INR

- 1 Unit

Gravity Die Castings Product Specifications

- Gravity Die Casting

- Silver

- Polished

- 1 to 25 kg

- Pressure Die Casting

- Industrial Casting

- Automotive, Engineering, Electrical Industries

Gravity Die Castings Trade Information

- as per requirements Per Day

- As per requirement Days

- Yes

- All India

Product Description

As an affluent firm in this field, we are devoted in offering our esteemed clients with an exceptional quality array of Aluminium Gravity Die Castings. Under the stern guidance of adroit professionals, the provided castings are manufactured using supreme grade raw materials and advanced techniques. Find their applications in different industries such as automotive and metal fabrication, these castings are used for molding purpose. Furthermore, the offered Aluminium Gravity Die Castings can be availed by our precious patrons at cost effective rates.

Features:

- Sturdy design

- Extended strength

- Long life

- Fine finish

Superior Customization & Precision

We manufacture aluminium gravity die castings according to your specific drawings and design requirements. Our process supports a wide range of custom geometries and sizes, with precise tolerances down to 0.05 mm, ensuring that every piece meets stringent application demands in automotive, engineering, and electrical industries.

Guaranteed Quality & Rigorous Testing

Every casting undergoes 100% pressure testing, adhering to IS, ASTM, or custom specifications. Our robust quality assurance guarantees corrosion resistance, polished surface finish, and longevity for each component, giving you peace of mind and reliable end products.

FAQs of Gravity Die Castings:

Q: How are gravity die castings manufactured using aluminium alloy?

A: Gravity die castings are created by pouring molten aluminium alloy into a metal mould under the force of gravity. This method allows for precise control over the shape and dimensions, resulting in a smooth surface finish and consistent quality tailored to custom specifications.Q: What types of applications are these castings suitable for?

A: These aluminium gravity die castings are widely used in automotive, engineering, and electrical industries due to their durability, corrosion resistance, and ability to meet complex geometric and performance requirements.Q: When is it ideal to use gravity die casting over other casting processes?

A: Gravity die casting is particularly advantageous when you need medium to large production volumes with consistently tight tolerances, superior surface finish, and robust mechanical propertiesespecially for parts weighing between 1 kg to 25 kg.Q: Where are your gravity die castings produced and exported from?

A: All our gravity die castings are manufactured in India, with an established export and supply network to serve both domestic and international clients, ensuring timely delivery and adherence to global standards.Q: What is the significance of 100% pressure testing in your process?

A: 100% pressure testing ensures that every casting is leak-proof and structurally sound, providing enhanced safety and longevity for critical components, especially in automotive and engineering applications.Q: How should these castings be packed and stored for safe transport?

A: Each component is meticulously packed in sturdy wooden boxes or cartons, protecting the polished, silver-finished surfaces from damage and corrosion during transit and storage.Q: What are the main benefits of choosing your aluminium alloy gravity die castings?

A: Choosing our castings offers high corrosion resistance, precise tolerances, customized shapes, consistent quality, and reliable performanceideal for demanding industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email